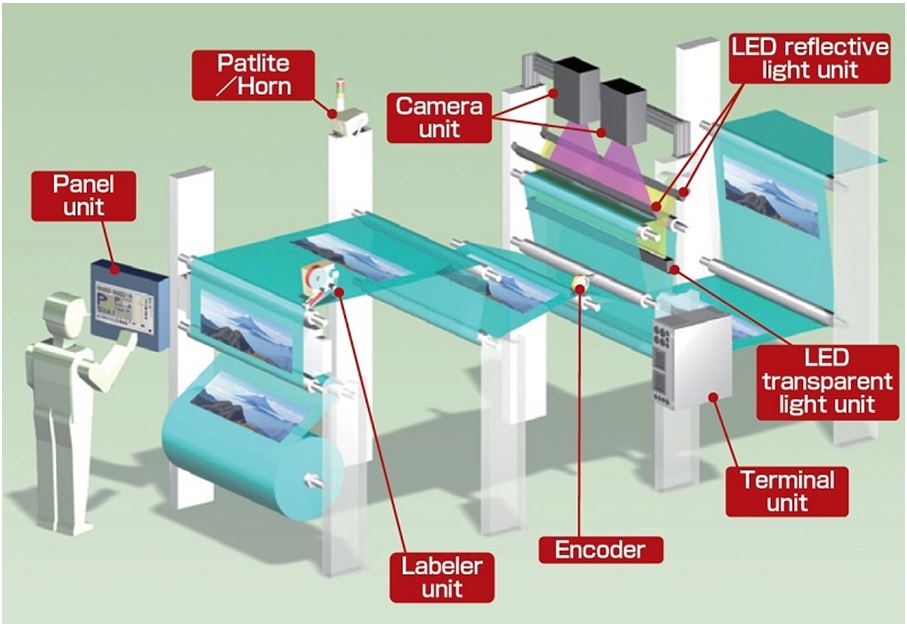

Print quality inspection device P-CAP V6

Printing InspectionThe inspection capability has been further improved.We can use it to reduce the defect rate and ensure print quality.

Main Features

1.Beautiful imagery with powerful inspection capabilities

- Inspection performance greatly enhanced with eight-mode simultaneous processing capability

- Specialized inspection for streaks

- Prioritization with severe defects output first

- Process algorithm with expanded defects detection function

- Proprietary lens-equipped high-speed digital cameras with high color-rendering LED light sources

2.Enhanced solutions for tension control and meandering problems

Tokyo Keiki's exclusive partial image shift processing and real-time automatic repeat length correction solves tensioning & meandering problems and enhances inspection within printed designs.

3.Small in size but boasting powerful high-speed image processing capability

System's image processing board incorporates Tokyo Keiki-designed & developed DAPDNA dynamically reconfigurable processor. Downsized inspection console with faster image processing speeds.

4.High maintainability and reliability

Reduced number of parts with assured quality based upon severe environmental testing. The DAPDNA dynamically reconfigurable processor changes its internal hardware configuration to achieve maximum image processing speeds. We can also sell the processor if you are interested.

Main Specifications

- Differing levels of inspection (3 levels and 1 mask) for different areas

- Inspection history data viewer function

- Double side inspection capability (different repeat length possible)

- Data processing with Microsoft SQL Server

- (Optional) Color trend monitoring function

- (Optional) Tablet support

P-CAP V6 installable for

- Rotogravure, flexographic, offset, business form printing and other systems

- Inflation/sheet making, coating, laminating, rewinding, slitting, etc.

ARG PACKAGING SOLUTIONS © All Rights Reserved. Developed by SDAD TECHNOLOGY