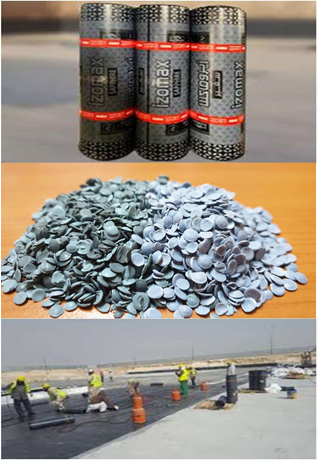

Bitumen

Description

Elastic polymer used for Bitumen applications to improve durability especially against natural elements such as water, UV radiation, and ozone attacks. It has a high thermal resistance, high permeability and contains Rubber and PE.

Typical properties:

- Density 0.84-0.88 g/cm³

- MFI 0.1-0.5 g/10 min

Key features

- Good process-ability.

- Excellent thermal durability.

- Water resistant.

- Resistance against UV radiation and ozone attacks.

Typical applications

Various Bitumen applications such as coatings, pavements, and roofing applications.

Anti Oxidant

Anti-oxidant masterbatch developed for the protection of polyolefin during processing and long term exposure.

Key features

- Decreases material deterioration and MFI change.

- Prevents yellowing of material during processing or long life exposure and decreases color change with time.

Typical applications

Blown and cast films.

Injection and blow molded plastic.

Extruded sheet.

Addtives

Dehydrated Additives:

Description

Dehydrated additives absorb residual or trace amounts of moisture.

Key features

- Good dispersing and flow properties.

- Has good anti blocking properties.

- Eliminate fisheyes after using DA-65.

Typical applications

Blown and cast films.

Injection and blow molded plastic.

Extruded sheets.

UV Masterbatches

Product benefit:

Excellent UV resistance to meet end use requirements optimal balance between UV stability and long-term thermal stability tailored products as per end use requirements good processability.

Applications and Recommended UV Stabilizer System

- Polyolefin films (for thin wall thickness like film, HALS is more efficient UV stabilizer than UV absorbers).

- Polyolefin injection molded (synergistic HALS mixture).

- PP fiber pigmented (Combination masterbatch between HALS and UV absorber).

- PP pipes (HALS).

ARG PACKAGING SOLUTIONS © All Rights Reserved. Developed by SDAD TECHNOLOGY